PPSU is a great material for reusable medical tools. It stays strong and looks good after many sterilizations. For example, PPSU keeps 90% of its strength after 275 steam cleanings. Regular plastics only keep 82%. It is safe for healthcare use and lasts a long time. As a professional supplier of high-performance PPSU profiles, Shengwen New Materials offers rods, sheets, and custom-processed components tailored for demanding sterilization environments in the medical industry.

PPSU is tough and lasts long for medical tools. It keeps 90% of its strength even after 275 steam cleanings.

PPSU handles high heat up to 134°C. This makes it great for cleaning many times without damage.

Medical devices made with PPSU save money. They last longer and need fewer replacements.

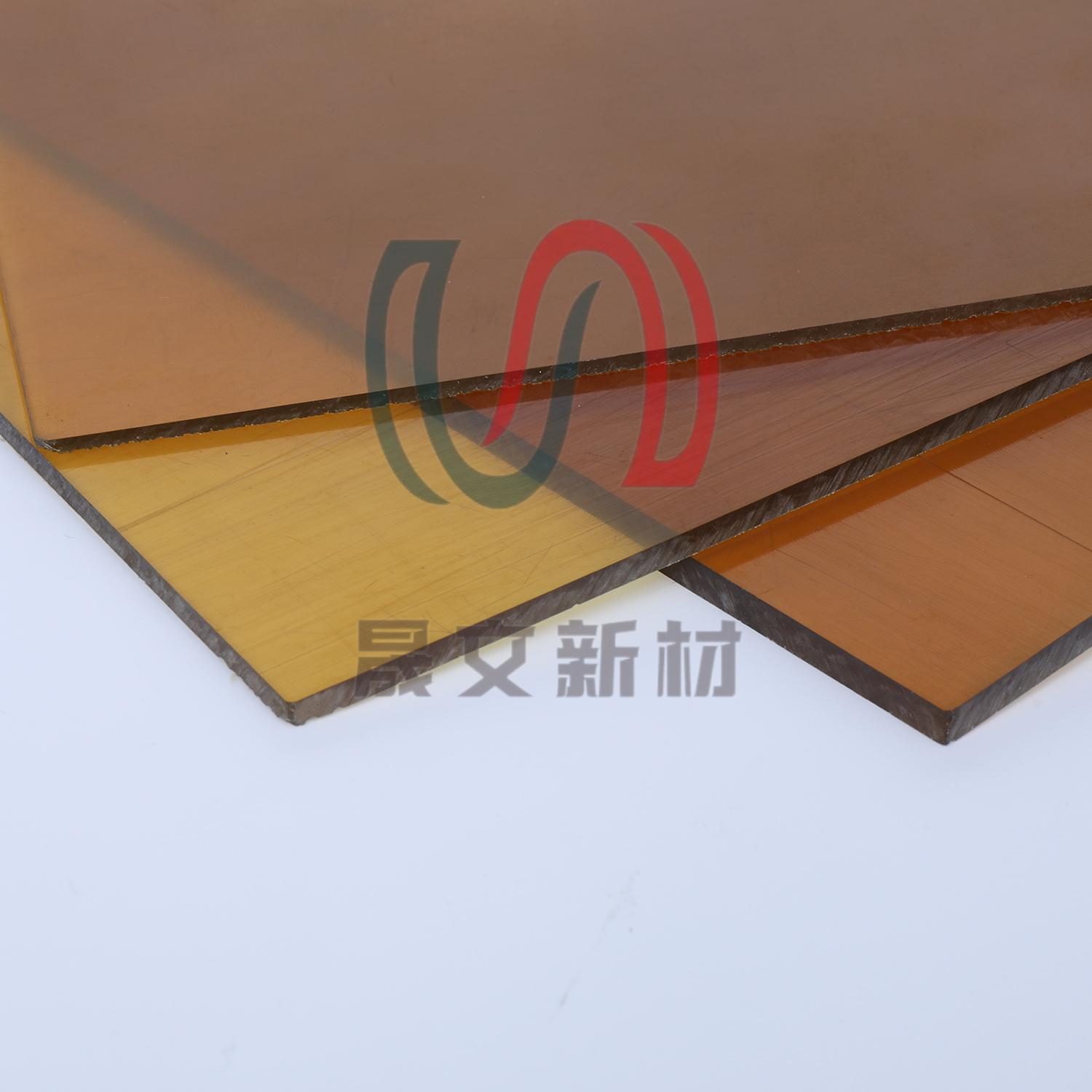

Shengwen offers medical-grade PPSU profiles (including rods and sheets) designed to meet repeated sterilization needs.

PPSU, a strong plastic, handles heat very well. It works great for medical tools cleaned with high heat. It can survive temperatures up to 134°C during cleaning. Even after many steam cleanings, it stays strong and stable. This means it won’t break or weaken easily. Medical tools made from PPSU last longer because of this.

Shengwen’s PPSU profiles are manufactured from materials with a high HDT/A (ISO 75) of 196℃ and a long-term RTI of 180℃, ensuring dimensional stability and durability even after 1,000+ autoclave cycles.

PPSU is tougher than most medical plastics. It can handle over 1,000 cleanings without losing strength. It is very strong, with an impact resistance of 690 J/m and a tensile strength of over 10,000 psi. These qualities make it perfect for hard-working medical tools.

Whether you need sterilization trays, dental equipment components, or surgical handles, PPSU profiles from Shengwen offer the toughness needed for repeated clinical use.

PPSU is safe to use in medical tools and implants. It meets strict rules for long-term use in healthcare. It doesn’t harm human tissues, making it safe for surgeries and implants. PPSU also resists harsh cleaning chemicals, adding another layer of safety and reliability.

All PPSU profiles from Shengwen are based on certified medical-grade raw materials that meet international compliance standards.

PPSU is very strong against steam and chemical cleaning. It can handle high heat during cleaning, up to 273°F (134°C). This helps tools stay strong after many cleanings.

Compared to PSU, PPSU works better. PSU only handles up to 250°F (121°C) and fewer cleaning methods. PPSU supports more, like ethylene oxide, gamma rays, and hydrogen peroxide:

|

Material |

Steam Heat Limit |

Cleaning Methods Supported |

Cleaning Cycles Lasted |

|

PSU |

250°F (121°C) |

Ethylene oxide, gamma |

Hundreds |

|

PPSU |

273°F (134°C) |

Ethylene oxide, gamma, hydrogen peroxide |

Up to 800+ |

These performance metrics also apply to our precision PPSU profiles, which are widely used in sterilizable component fabrication.

PPSU stays strong and looks good after many cleanings. It can handle over 1,000 steam cleanings without breaking down. Its water resistance keeps it from damage caused by moisture.

|

Test Type |

Result |

|

High Heat Use |

About 400°F |

|

All Cleaning Methods Cycles |

Over 100 cycles |

|

Steam Cleaning Cycles |

Over 1,000 cycles |

|

Water Damage Resistance |

Very high |

|

Chemical Resistance |

Excellent against hospital cleaners |

PPSU profiles retain structural integrity and optical clarity over long periods, making them reliable for long-term device use.

PPSU saves money for medical tools over time. It handles many cleanings without breaking. This means fewer replacements. Its long life helps hospitals reduce overall procurement costs.

By using standardized or custom PPSU profiles, device manufacturers can also reduce production time and material waste, resulting in more efficient manufacturing.

PPSU is useful for many medical tools. It is safe for the body and handles cleaning well. It can be shaped into detailed designs, making it ideal for both standard and custom parts.

Shengwen provides customized PPSU profiles that are colorable, transparent, or flame retardant depending on OEM/ODM requirements, enabling flexible medical device designs.

PPSU meets strict rules, making it safe for medical use. It follows FDA rules, ISO 10993, and USP Class VI requirements:

|

Standard |

Description |

|

FDA |

Safe for food and medical contact |

|

GMP |

Ensures plastics are made under strict controls |

|

USP Class VI |

Tests materials for medical tools and injections |

|

ISO 10993 |

Verifies safety in body contact applications |

Shengwen’s PPSU profiles are based on materials that comply with these global standards, ensuring peace of mind for both manufacturers and end-users.

It handles heat, stays strong, and is safe for the body. Unlike other plastics, PPSU stays tough after many cleanings. Hospitals like it because it saves money and meets strict safety rules.

PPSU is stronger, safer, and handles heat better. It stays tough and looks good after many cleanings, unlike other plastics.

Yes, PPSU works with steam, chemicals, and radiation cleaning. It fits many cleaning ways used in hospitals.

PPSU meets FDA, ISO 10993, and USP Class VI rules. These prove it is safe for long use in tools and implants.

At Shengwen New Materials Co., Ltd., we specialize in the production and custom processing of high-performance PPSU profiles. Our offerings include industrial-grade and medical-grade PPSU rods, sheets, and machined parts tailored for repeated sterilization in medical environments.

We provide:

Whether you’re designing a high-durability medical device or enhancing your product’s lifecycle and safety, Shengwen delivers material reliability and technical support to help your vision succeed.

By continuing to use the site you agree to our privacy policy Terms and Conditions.