When it comes to manufacturing ball valves, bearings, and other electrical equipment components, we frequently mix up PTFE and PEEK. Despite the fact that they both belong to the same polymer family, they have distinct benefits and shortcomings. Today we will have a comparison with them.

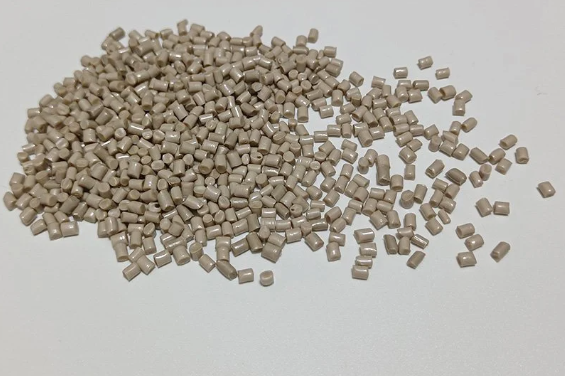

PEEK, or Polyetheretherketone, is a high-performance thermoplastic polymer known for its exceptional chemical resistance, high temperature stability, and robust mechanical strength. Additionally, materials within the PSU (Polysulfone) or PES (Polyethersulfone) families share similar characteristics. PEEK exhibits low moisture absorption, making it dimensionally stable, and is biocompatible, suitable for certain medical applications. Commonly utilized in aerospace, automotive, electronics, and medical industries, PEEK and related materials like PSU or PES are chosen for applications requiring durability and superior performance in demanding environments.

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer with exceptional qualities, including excellent chemical and temperature resistance, durability, and dielectric properties. Commonly known as Teflon, PTFE is widely used in everyday items such as cookware pans and automobile parts. It is an industrially popular material used for coating non-stick fry pans, medical equipment, and automotive machinery. The term Teflon is a trademark referring specifically to PTFE. Unlike thermoplastic PTFE, which undergoes traditional polymer processing, PTFE has high viscosity and is processed through cold shaping followed by heat treatment (sintering) to create a solid molding.

Here's a concise comparison of properties between PEEK and PTFE to assist in new product development. We compare PEEK and PTFE in 4 ways.

When it comes to polymers, there are few things which have harder strength than PEEK. In fact, it's so strong that the same machining guidelines apply to PEEK and metal.

This strength allows PEEK to be used in applications such as gaskets and automotive parts, especially where the metal cannot be used but metal-like durability is required.

PEEK melts at around 400 degrees Celsius and can work in an environment of 300-325 degrees without deformation. While PTFE can withstand temperatures up to 250 degrees, any pressure on PTFE at this temperature will inevitably lead to deformation. In the case of PEEK, its hardness allows it to be used in high-stress, high-temperature environments without losing its formability.

Likewise, while both PTFE and PEEK can withstand significant wear, PEEK has a high PV that can withstand wear even under harsh physical and chemical conditions.

While PEEK is not an exact match to PTFE in terms of pure chemical inertness, it is resistant to many harsh chemicals, allowing it to be used in corrosive environments.

Need a table to present the comparison of the differences

| Specification | PTFE | PEEK | Preferred material |

| Price | Moderately expensive | Very expensive | PTFE |

| Tensile Strength | 25-35 Mpa | 90-100 Mpa | PEEK |

| Elongation | 350-400% | 30-40% | PTFE |

| Compressive Strength | 30-40 Mpa | 140 Mpa | PEEK |

| Flexural Modulus | 495 Mpa | 3900 Mpa | PEEK |

| Coefficient of Friction | 0.03-0.05 | 0.35-0.45 | PTFE |

| Temperature resistance | Up to 250°C | Up to 250°C | NA |

| Dielectric strength | 50-150 Kv/mm | 50 Kv/mm | PTFE |

| Chemical resistance | Virtually inert | Affected by Sulphuric acid | PTFE |

| Coefficient of linear thermal expansion | 14 x 10-5/K | 5 x 10-5/K | PEEK |

| Machine-ability | Good | Very good | PEEK |

In summary, PEEK is preferred for applications demanding strength and low deformation, while PTFE excels in applications requiring resistance to voltage or chemicals. PTFE's self-lubricating properties make it a top choice for high-wear applications. The choice between the two depends on the specific performance characteristics needed for a given application in new product development.

For any more information, please do not hesitate to contact us.

By continuing to use the site you agree to our privacy policy Terms and Conditions.