PES

What is PEI Resin (Polyetherimide)

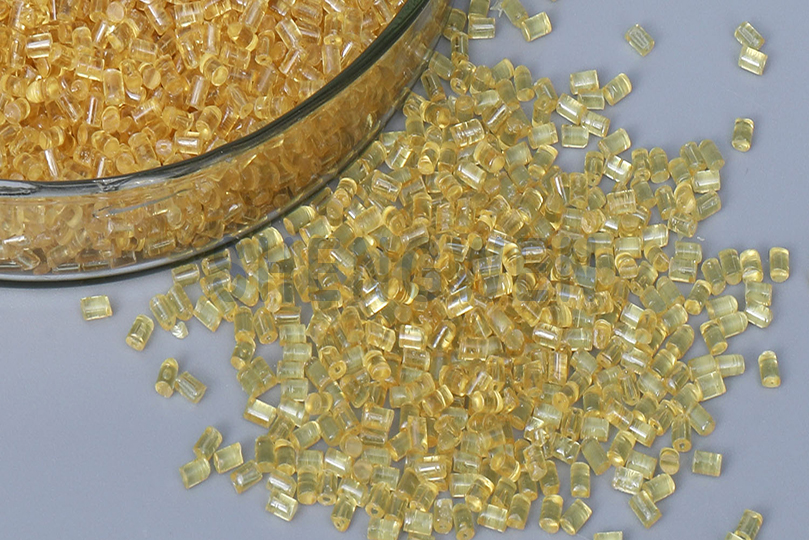

Polyetherimide, universally known by its abbreviation PEI, represents one of the most capable high-temperature plastics in the engineering thermoplastic family. It is an amorphous, amber-transparent material that delivers an exceptional balance of properties, positioning it as a premier high-performance polymer for demanding applications.

Within the category of advanced thermoplastics, PEI stands out for its inherent stability and strength. As a heat-resistant plastic, it maintains its integrity where standard materials fail.

Key Characteristics & Advantages of PEI Polymer

This thermoplastic resin offers a unique combination of attributes that make it a superior material choice:

- Exceptional Thermal Performance: High strength and rigidity at elevated temperatures, with long-term heat resistance and excellent dimensional stability.

- Inherent Safety & Durability: Naturally flame retardant (UL94 V-0) without additives, with good resistance to chemicals, UV light, and weathering.

- Reliable Electrical & Mechanical Properties: Stable electrical insulation under variable conditions and significant creep resistance, enabling it to replace metals in structural applications.

The versatility of this engineering plastic makes it invaluable across technologically advanced industries.

Tuntun Plastic: Your PEI Material Solutions Partner

Tuntun Plastic specializes in transforming raw PEI polymer into finished solutions. We provide a comprehensive range of semi-finished and custom products, leveraging deep expertise in material science and precision manufacturing.

Our Core PEI Product Forms:

With proven capability in machining, injection molding, and creating custom profiles, we deliver precision and versatility. Whether your project requires unique prototype parts or high-volume production components, we are committed to providing the most effective PEI plastic solution.

Polyetherimide Specifications and Properties

The following data quantifies the performance of our standard Polyetherimide (PEI) engineering resin:

| Properties | Test Method | Test Conditions | Unit | Values |

| Density | ASTM D792 | / | g/cm3 | 1.27 |

| Heat Distortion Temp. | ASTM D648 | 1.8MPa, 6.4 mm | ℃ | 201 |

| Melt Flow Rate | ASTM D1238 | 337℃, 6.6kg | g/10min | 9 |

| Tensile Strength | ASTM D638 | 5mm/min | MPa | 110 |

| Tensile Modulus | ASTM D638 | 5mm/min | MPa | 3600 |

| Flexural Strength | ASTM D790 | 2.6mm/min | MPa | 165 |

| Flexural Modulus | ASTM D790 | 2.6mm/min | MPa | 3500 |

| Impact Strength, Notched | ASTM D256 | 23℃ | J/m | 53 |

| Flammability | UL94 | 1.5mm | Class | V-0 |

Typical Application

Pei resins have high heat, flame, and solvent resistance, making them perfect materials for connectors, medical, chemical instruments, automotive, aerospace, 5G and food production industries.

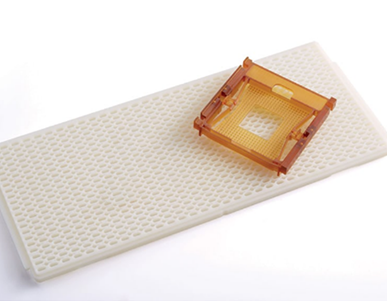

IC Tray

Individually Ventilated Cages

PEI Boards and Rods

FAQ:

What is PEI material?

Polyetherimide (PEI) is an amorphous high-performance engineering thermoplastic known for its high mechanical strength, rigidity, and thermal stability. It is the technical name for the class of materials that includes branded products like SABIC's ULTEM™ resin. When specifying materials for your project, using the generic term "PEI" along with required performance parameters ensures you receive the appropriate material grade.

Q1

What is polyetherimide used for?

PEI is a versatile high-temperature plastic used in aerospace, automotive, and electronics for its strength and heat resistance. It's also found in medical devices and industrial components, offering biocompatibility and flame retardancy.

Q2

Whether to provide the sample and the delivery time of the sample ?

We can provide a sample of 3kg in stock within 5 working days.

Q3

Do you offer customization services for PEI resin?

Yes. We offer full customization, including adding fillers (glass fiber, carbon fiber) and manufacturing boards/rods to specific sizes. Click for details to learn more>>

Q4

Can polyetherimide be 3D printed?

Yes, Polyetherimide can be 3D printed. PEI is known for its excellent thermal and mechanical properties, making it a suitable material for 3D printing, especially in highly demanding applications. It is used in resin form for creating 3D printed, high-strength prototypes and parts.

Q5

Can you provide the quality certificate of the products?

Of course. All of our products are proven to be perfectly compliant with FDA, REACH and RoHS safety regulatory, and so on. If you need, you can contact us to check the relevant documents.

Q6

Is polyetherimide (PEI) an expensive plastic?

The cost of Polyetherimide (PEI) varies depending on factors such as grade, form (sheets, rods, filaments), and supplier. Generally considered a high-performance engineering thermoplastic, PEI tends to be more expensive than common plastics. The unique combination of properties, including high mechanical strength and thermal resistance, contributes to its higher cost. Specific pricing details would depend on the source and market conditions at the time of purchase. It's advisable to consult suppliers or manufacturers for current and specific pricing information.

Q7

Are you manufacturer or trading company?

We are integral part of industry and trade. Both the agency of some products, but also a factory for product development and production.

Q8

About bulk order leading time?

It will take about 15~30 working days from order confirmation to production completion. Specific communication can be coordinated to the time acceptable to both side.

Q9

How to Process PEI?

Unlike most other polyimides, PEI is suitable for processing by typical methods such as injection molding, extrusion, thermoforming, and compression molding.

Q10