Polyethersulfone (PES) is a high-performance engineering plastic known for its ability to retain mechanical strength, dimensional stability, and chemical resistance under extreme conditions. In particular, its stable performance in high-temperature and steam environments makes PES a trusted material in medical, industrial, automotive, and thermal fluid applications. Understanding how PES behaves under continuous heat, hot water, and pressurized steam helps explain its wide adoption in demanding fields.

To begin with, thermal resistance is one of the most important properties of PES. It has a heat deflection temperature of around 200–220°C and a recommended continuous use temperature of 180–200°C. In addition, its UL temperature index reaches 180°C, confirming its ability to maintain long-term stability under sustained heat exposure.

Because of this high thermal endurance, PES components can operate reliably where many common thermoplastics soften or deform. This makes PES especially suitable for parts exposed to repeated or long-term thermal cycles rather than short-term heat.

Beyond dry heat, PES also performs very well in hot water and steam environments. It can withstand exposure to 150–160°C hot water or steam without significant degradation. At the same time, PES remains resistant to acids and alkalis, showing strong hydrolysis resistance.

As a result, PES does not suffer rapid molecular breakdown when exposed to heat and moisture together. This makes it reliable for steam-rich environments such as sterilization systems, hot water valves, and fluid handling equipment, where long-term durability is critical.

In addition to thermal resistance, PES maintains excellent mechanical stability over a wide temperature range. Its modulus remains nearly unchanged from very low temperatures up to around 200°C, and above 100°C it retains stiffness better than most thermoplastics.

Equally important, PES shows outstanding creep resistance at temperatures below 180°C. This means it can maintain shape and load-bearing ability over long periods under stress. Glass fiber–reinforced PES performs even better, making it suitable for parts exposed to constant load in hot and steam-filled environments.

Another key advantage of PES is its dimensional stability under temperature changes. Its coefficient of linear thermal expansion is low and remains stable with rising temperature. For example, 30% glass fiber–reinforced PES has a thermal expansion coefficient close to that of aluminum and stays stable up to 200°C.

This property is especially valuable for components requiring tight tolerances. In hot water and steam systems, good dimensional stability helps prevent leakage, misalignment, and assembly failure, improving long-term reliability.

In addition to heat and steam resistance, PES also offers strong chemical stability. It resists fuels, lubricating oils, and many cleaning agents, including fluorinated solvents. Among amorphous plastics, it has excellent resistance to solvent stress cracking.

Although PES has limitations with some highly polar solvents, its overall chemical resistance allows it to perform reliably in harsh industrial environments, especially when combined with heat and moisture exposure.

Thanks to these combined properties, PES is widely used in hot water and steam valves, pump parts, ultrafiltration systems, and radiator components. In medical and laboratory equipment, it withstands repeated steam sterilization, making it suitable for reusable housings and filtration devices. In electrical and electronic applications, PES is valued for insulation parts, connectors, and motor components that face thermal stress.

In summary, PES offers a rare combination of high thermal resistance, excellent steam and hydrolysis stability, strong creep resistance, and reliable dimensional control. These proven properties make it a dependable material for high-temperature and steam applications across many industries.

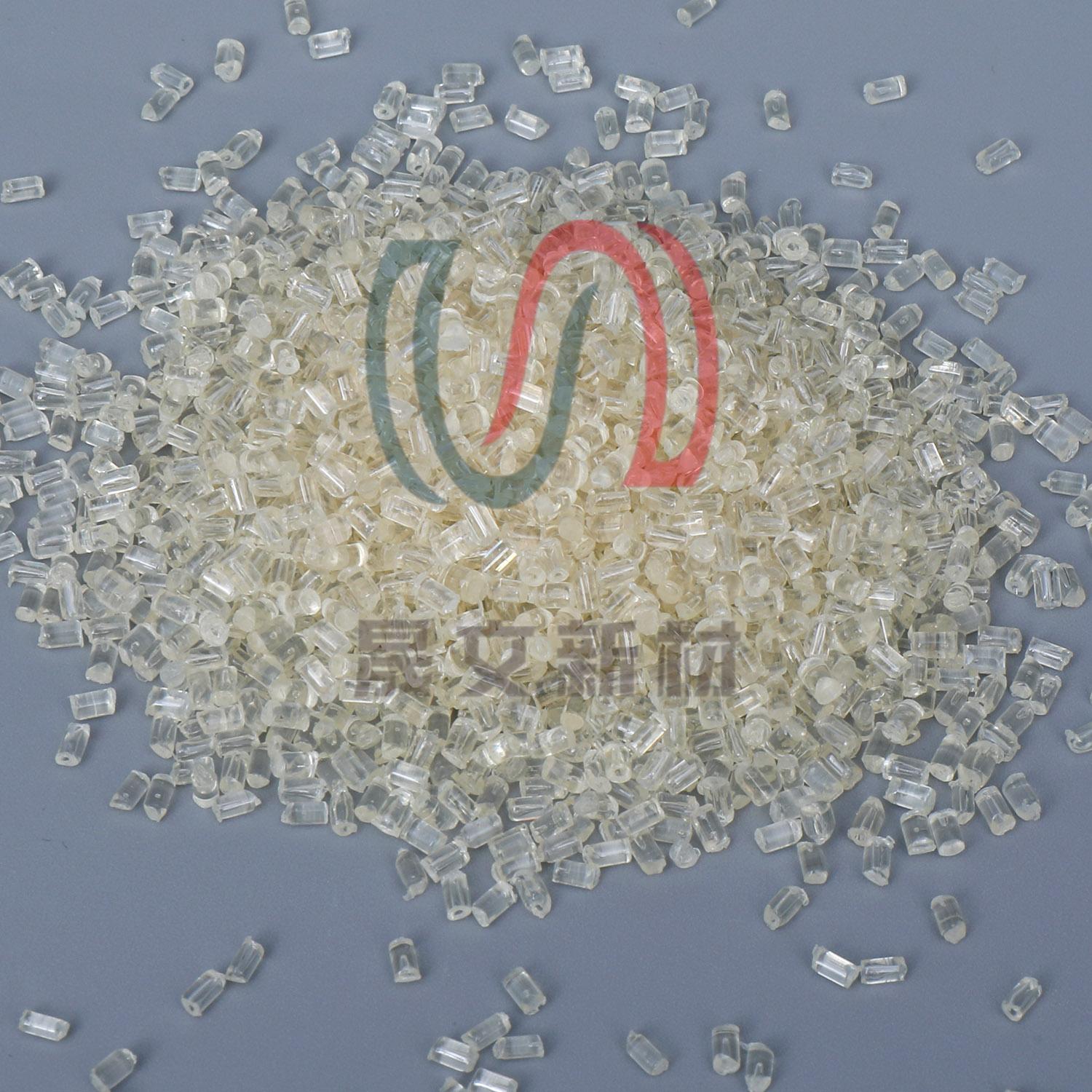

As a professional supplier of high-performance engineering plastics, Shengwen New Materials provides PES rods and boards designed for demanding thermal environments. If you are seeking a stable material solution or a trusted PES supplier, Shengwen is ready to support your project with reliable quality and technical expertise.

By continuing to use the site you agree to our privacy policy Terms and Conditions.