Materials like PPSU are very important in electrical insulation. PPSU profiles, made through specialized extrusion or molding processes, offer high strength and excellent heat resistance, making them ideal for advanced electrical systems. With outstanding thermal stability and toughness, PPSU profiles provide safe and reliable insulation even under the most demanding conditions. Today, more electronics and industrial companies are choosing PPSU profiles to produce connectors, sockets, enclosures, and high-voltage components, demonstrating the growing demand for innovative electrical insulation solutions.

PPSU, short for Polyphenylsulfone, is a top-grade thermoplastic known for its strength, heat resistance, and excellent durability. Unlike general plastics, PPSU maintains its stability and mechanical properties even at high temperatures and in harsh environments, which is why it's widely used in aerospace, automotive, medical, and increasingly in electrical insulation applications.

When processed into profiles and shaped components, PPSU becomes especially valuable for electrical insulation systems, providing both structural strength and outstanding electrical safety where performance matters most.

PPSU profiles possess a unique combination of features that make them particularly suitable for electrical applications:

|

Property |

Value |

|

Long-term heat resistance |

230 °C |

|

Short-term heat resistance |

260 °C |

|

Glass transition temperature |

97 °C |

|

Melting point |

281 °C |

|

Flame resistance |

UL94 V-0 |

|

Tensile strength |

High |

|

Impact resistance |

690 J/m |

|

Dimensional stability |

Excellent |

|

Hydrolytic stability |

Exceptional |

These characteristics enable PPSU profiles to perform reliably in high-demand electrical systems.

PPSU profiles are widely used for high-voltage components such as insulators, bushings, and connector housings. Thanks to their flame resistance, dimensional stability, and high dielectric strength, PPSU profiles provide long-lasting protection against electrical and environmental stresses.

|

Property |

Benefit |

|

High flame resistance |

Reduces fire risk in high-voltage systems |

|

Excellent dielectric strength |

Ensures safe electrical isolation |

|

High mechanical toughness |

Resists mechanical shock and stress |

|

Weather resistance |

Suitable for outdoor and industrial environments |

PPSU’s robustness also helps prevent failures during electrical faults, enhancing overall system safety.

PPSU profiles are also used in circuit board supports, electronic enclosures, and component frames. Their superior heat resistance ensures that electronic assemblies maintain integrity even under high operating temperatures.

By integrating PPSU profiles into the design, manufacturers can achieve both mechanical protection and superior insulation for critical electronics.

Connectors and housings made from PPSU profiles provide outstanding protection in automotive, aerospace, and industrial applications. Their high RTI (Relative Thermal Index) of 180°C ensures safe performance even in high-temperature environments, while the material’s hydrolytic stability makes it ideal for humid or wet conditions.

PPSU profiles are essential for modern automotive and industrial electrical systems that demand high durability and resistance to extreme heat, chemicals, and environmental exposure.

In industrial plants, PPSU profiles are used to make enclosures, sensor housings, and protective covers that must endure corrosive substances and mechanical stress. In vehicles, they protect under-hood electrical parts, ensuring systems continue functioning safely even in aggressive environments.

Moreover, PPSU's lightweight nature contributes to overall system efficiency by reducing weight without sacrificing performance.

PPSU profiles exhibit outstanding resistance to heat deformation:

These properties ensure PPSU profiles retain their mechanical and insulating performance even in continuous high-temperature applications like motor controllers and power distribution units.

|

Property |

Test Method |

Metric |

Imperial |

|

Heat Deflection Temp |

ASTM D648 |

189°C |

372°F |

|

Glass Transition Temp |

DMA (SSYS) |

230°C |

446°F |

PPSU profiles offer high electrical resistivity (5×10³ Ω·cm) and excellent dielectric strength (16 KV/mm), making them ideal for insulating sensitive components and preventing short circuits or breakdowns even in high-voltage systems.

PPSU’s toughness and chemical resistance make it perfect for harsh industrial environments. Its ability to withstand impacts, steam sterilization, and chemical exposure without property degradation ensures long service life with minimal maintenance.

Compared to metals, PPSU profiles are lighter while maintaining high mechanical strength. They allow engineers to design complex, lightweight, and durable insulation structures, promoting energy savings and improved system efficiency.

By using PPSU profiles, manufacturers can achieve:

PPSU profiles help engineers build safer and more efficient electrical systems. Compliance with global safety and performance standards such as UL94 V-0, IEC 62368-1, and FCC regulations ensures that products using PPSU profiles meet the highest quality benchmarks.

PPSU profiles support the development of next-generation electrical insulation solutions by offering unmatched strength, temperature resistance, and design versatility. This allows for more compact, durable, and safer electrical devices.

Thanks to their exceptional durability and recyclability, PPSU profiles help reduce waste and environmental impact. Their use contributes to longer product lifecycles and energy-efficient systems, supporting global sustainability goals.

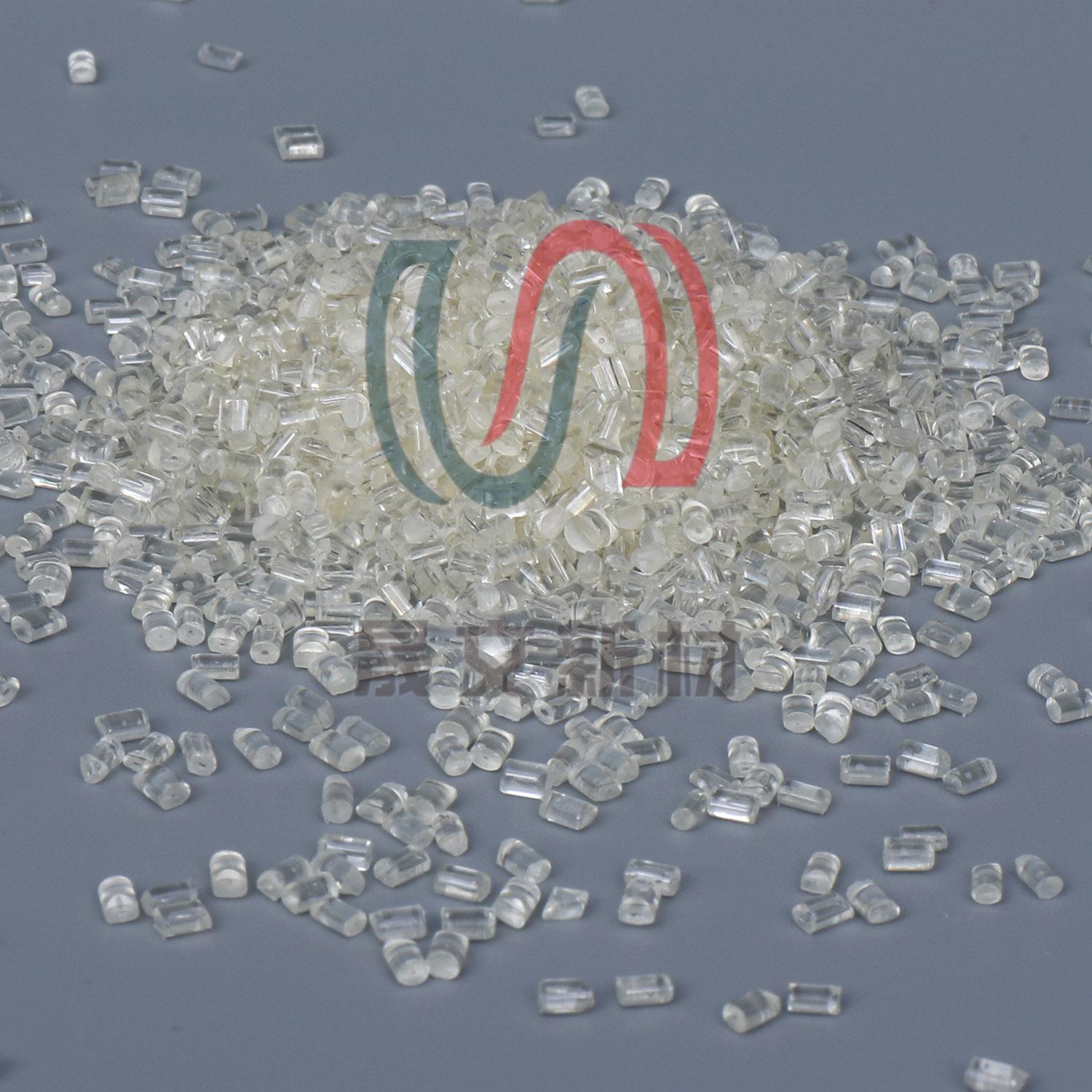

Shengwen New Materials is your trusted supplier of premium PPSU profiles tailored for advanced electrical insulation and industrial applications.

Available in natural (with high HDT/A of 196°C per ISO 75) and a wide range of colors including red, orange, yellow, green, blue, purple, white, gray, brown, and black.

Typical delivery: 15–30 working days after order confirmation.

Flexible schedule coordination to align with your project timelines.

By continuing to use the site you agree to our privacy policy Terms and Conditions.