The automotive industry is moving toward lighter, safer, and more energy-efficient vehicles. To achieve these goals, materials with excellent mechanical strength, chemical resistance, and durability are in high demand. Polysulfone (PSU), a high-performance engineering plastic, has become one of the preferred solutions in many automotive applications. With its outstanding balance of thermal stability, oil resistance, and dimensional reliability, PSU provides manufacturers with the performance they need while supporting industry trends such as lightweight design and longer service life.

Polysulfone (PSU) belongs to the polyarylether sulfone family. It is an amorphous plastic with a backbone made of aromatic rings and sulfone groups, which gives it excellent stability under harsh conditions. PSU can withstand temperatures ranging from -100 ℃ to 175 ℃ without losing its functional integrity. Its compressive strength reaches up to 280 MPa, ensuring that it can handle high mechanical stresses over time.

In addition to strength, PSU also demonstrates remarkable chemical resistance. It can resist fuels, lubricants, and various automotive fluids, making it suitable for demanding environments. Moreover, it has good electrical insulation properties, enabling its use in vehicle electrical systems. These combined features explain why PSU is increasingly chosen for both conventional and electric vehicles.

One of the most significant benefits of PSU is its ability to replace metals in many automotive parts. By using PSU instead of heavy metal components, manufacturers can reduce the overall weight of vehicles. This not only improves fuel efficiency in combustion engine cars but also extends driving range for electric vehicles.

Another advantage is PSU’s resistance to oils and fuels. In applications such as oil pumps, filters, and fuel system components, PSU ensures long-term durability and prevents damage caused by continuous contact with hydrocarbons. This reliability reduces the risk of part failure and minimizes maintenance costs.

PSU also offers high-temperature stability. Under the heat of engine compartments and braking systems, it maintains dimensional accuracy and structural strength. For example, PSU is used in headlamp rings and fog lamp reflectors, where high heat and long operating hours demand robust performance.

Dimensional stability is another crucial feature. Even when exposed to high humidity and mechanical loads, PSU parts remain accurate in size and shape. This makes the material highly suitable for fuse seals and other critical safety components where consistency is essential.

Finally, PSU provides design flexibility. With efficient processing methods such as injection molding and extrusion, it can be shaped into complex geometries while maintaining excellent surface finish. This allows automotive engineers to design innovative, lightweight, and cost-effective parts that meet both performance and safety standards.

Thanks to these benefits, PSU is already widely used in many automotive parts. Typical examples include:

These applications highlight PSU’s ability to perform in areas where both durability and resistance to challenging operating conditions are essential.

Beyond the automotive field, PSU is also gaining attention in hydrogen energy systems. As a clean energy source, hydrogen requires advanced technologies for efficient production and storage. Electrolyzers, which split water into hydrogen and oxygen, face challenges when built with traditional metals due to weight, corrosion, and high cost.

High-performance plastics like PSU provide an effective alternative. With its thermal stability, chemical resistance, and mechanical strength, PSU is well suited for components such as electrode frames in modern electrolyzers. Its ability to maintain dimensional stability under demanding operating conditions helps improve both efficiency and cost-effectiveness. This shows that PSU is not only valuable for automotive applications but also plays a role in the broader global energy transition.

Compared with other engineering plastics such as PEI, PPSU, or PA12, PSU offers a balanced combination of performance and cost. While PEEK provides even higher strength, it is often too expensive for large-scale automotive use. PSU, on the other hand, delivers sufficient durability, excellent oil resistance, and high-temperature tolerance at a more competitive price. This balance makes PSU a practical choice for many automotive and industrial applications.

The rapid growth of electric vehicles and hydrogen energy solutions is accelerating the demand for high-performance plastics. PSU stands out as a material that can meet both technical requirements and environmental regulations. Its potential for recyclability and its long service life contribute to reducing waste and improving sustainability in automotive manufacturing. As vehicle design continues to evolve toward lightweight and eco-friendly solutions, PSU will play an increasingly important role in shaping the next generation of cars and energy systems.

In summary, PSU offers a combination of lightweight design, oil and fuel resistance, high-temperature stability, dimensional accuracy, and processing flexibility. These features make it a reliable choice for automotive parts such as lighting components, oil systems, and electrical insulation. At the same time, PSU is expanding into hydrogen energy and electrolyzer applications, demonstrating its versatility and relevance to future technologies. With its proven performance and adaptability, PSU is set to remain an important material for both today’s vehicles and tomorrow’s energy solutions.

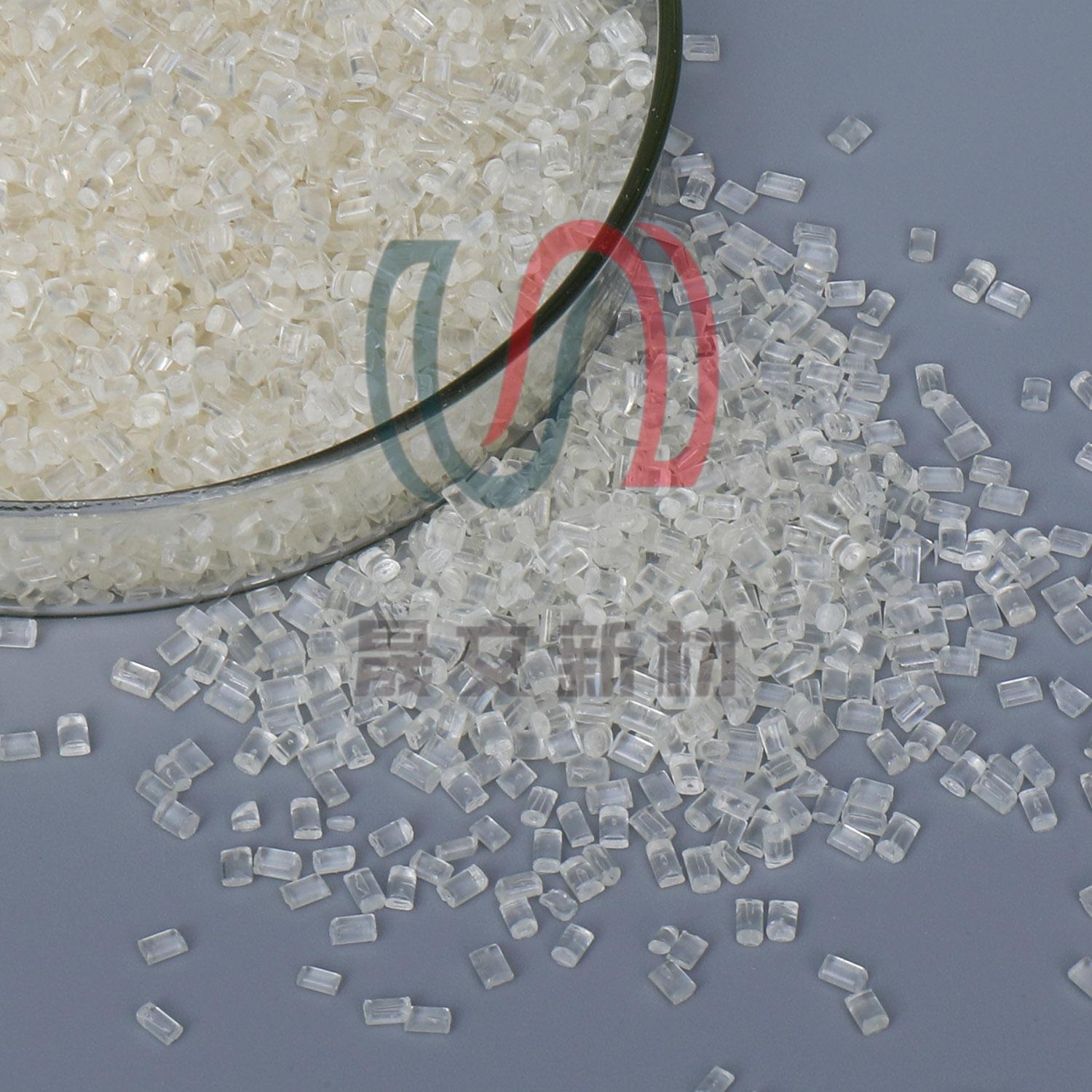

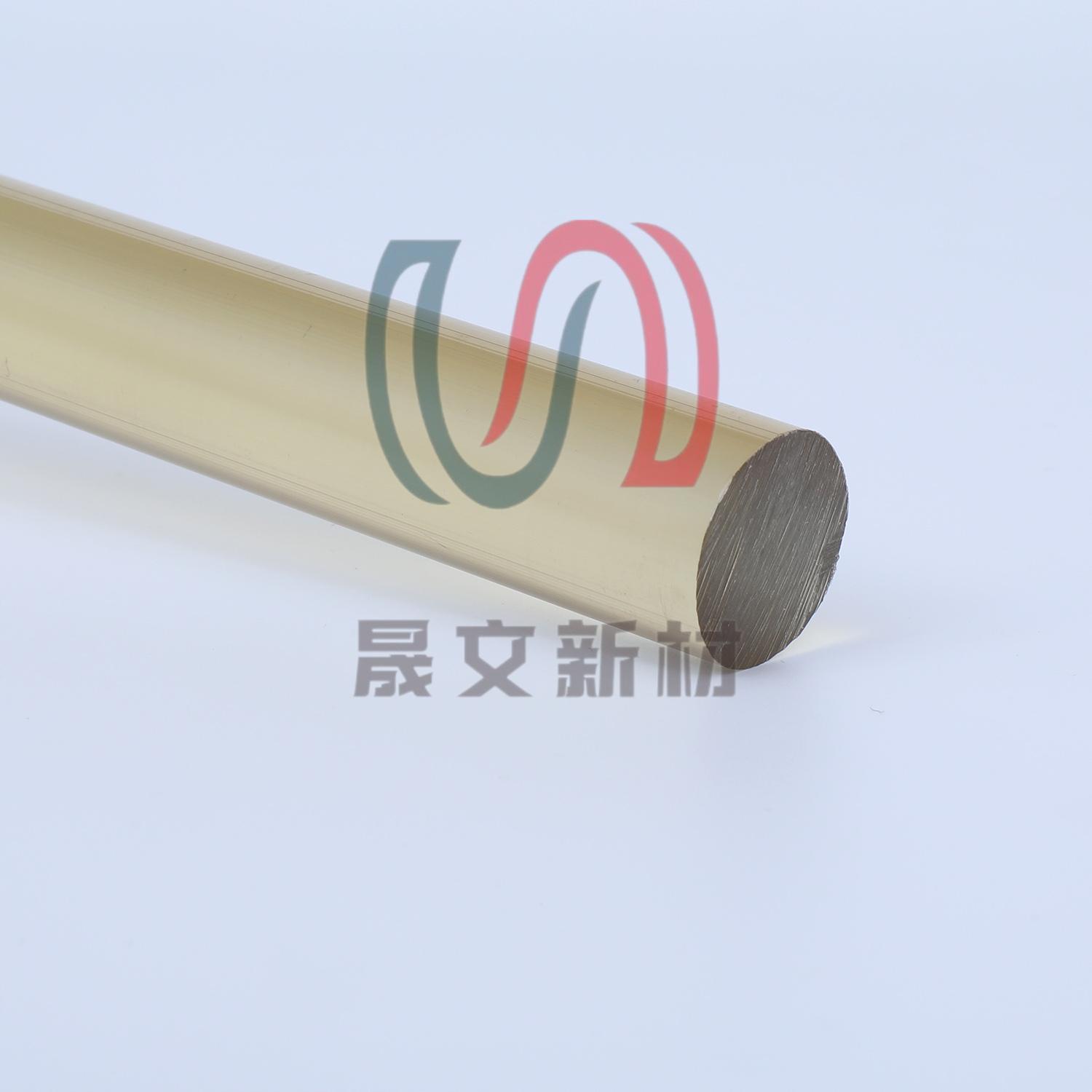

Shengwen is a trusted polysulfone supplier, providing high-quality PSU in the form of granules, boards, and rods. Contact us today to learn how our materials can support your automotive and industrial projects.

By continuing to use the site you agree to our privacy policy Terms and Conditions.