Polysulfone (PSU), sometimes also referred to as PSF, is a high-performance thermoplastic engineering material. Known for its high heat resistance, mechanical strength, and excellent dimensional stability, PSU is widely used in injection molding for producing precision and functional parts. Its unique balance of strength, electrical insulation, and resistance to creep and aging makes it a preferred choice for many industries. In this article, we will explore the application of PSU in injection molding, from material properties to process requirements and design considerations.

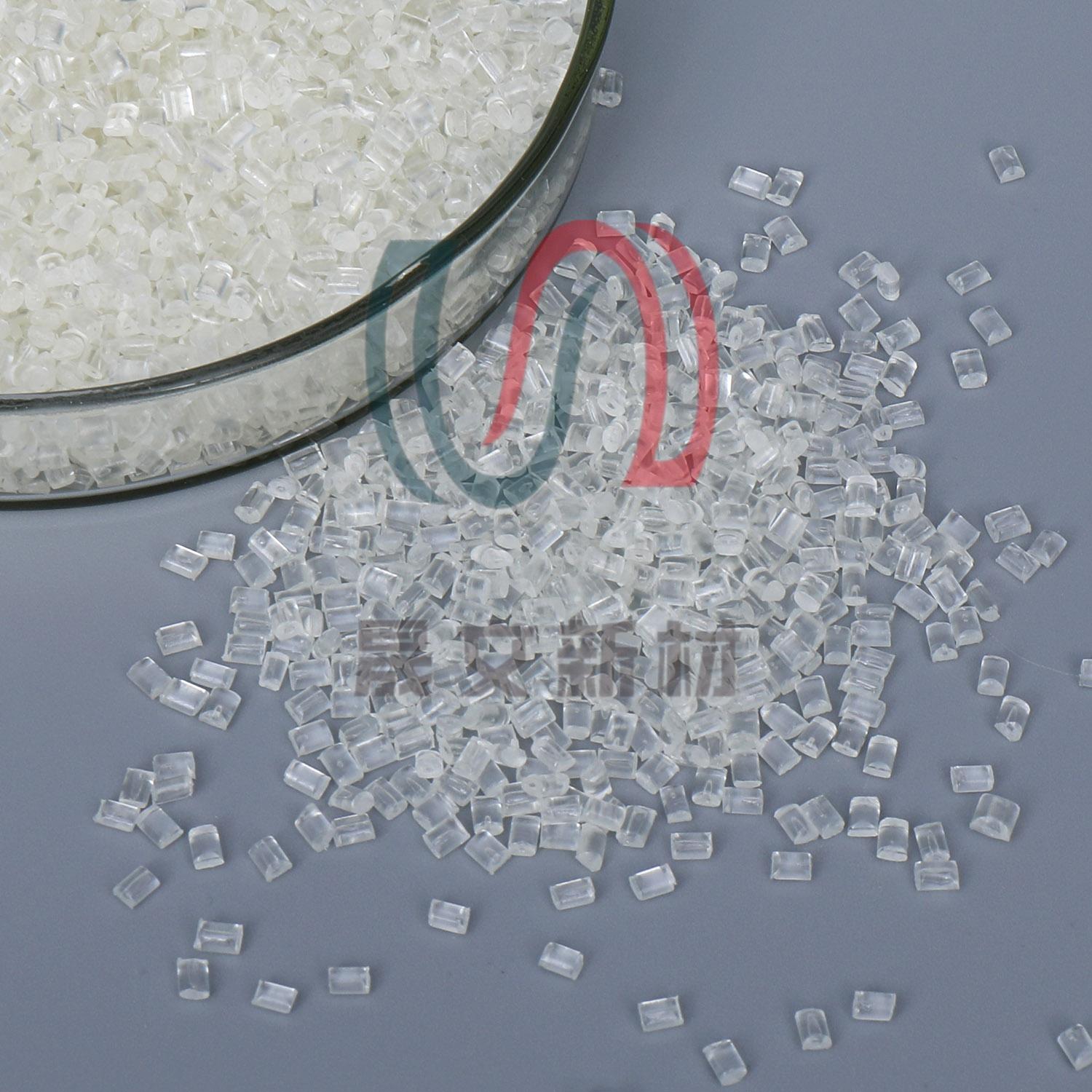

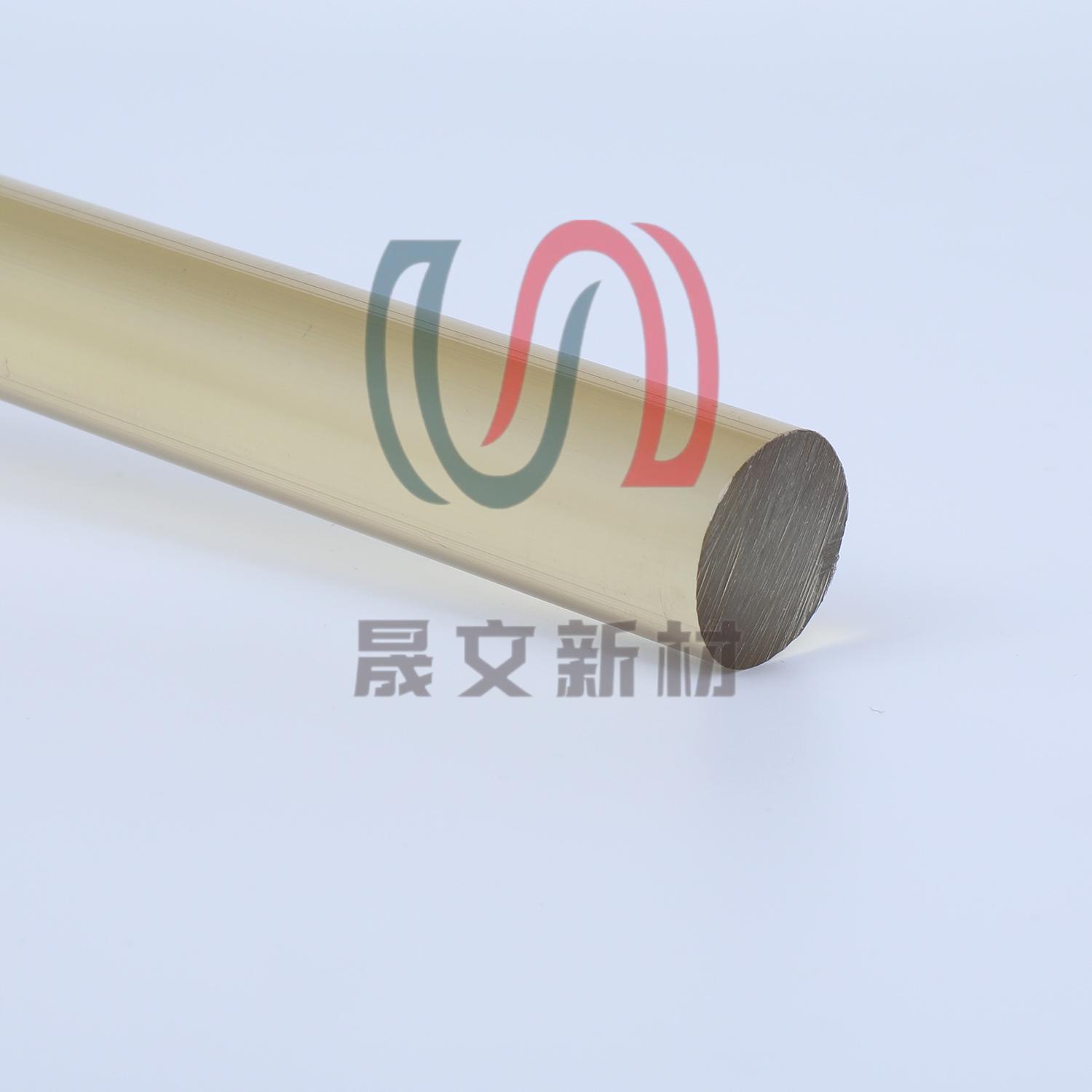

To begin with, PSU is an amorphous plastic with no clear melting point. Instead, it has a glass transition temperature (Tg) of about 190°C and requires molding temperatures above 280°C. Injection-molded PSU parts often display good transparency and mechanical strength.

One important characteristic of PSU is its melt behavior. It behaves similarly to PC (polycarbonate) with a high viscosity melt that shows sensitivity to temperature. While its viscosity decreases significantly when temperature rises above 330°C, the material still has relatively poor flowability. This makes mold design and processing parameters crucial to achieve defect-free products.

Additionally, PSU has low moisture absorption (around 0.6%), much lower than nylon. However, even small amounts of water can cause degradation during molding at high temperatures. Therefore, proper drying is always necessary before processing.

Due to its excellent thermal and electrical properties, PSU is used for a wide variety of functional injection-molded parts. Common applications include:

PSU’s performance in high-temperature and high-load environments makes it a valuable alternative to materials such as POM or PA66 when higher dimensional stability and heat resistance are required.

Like other engineering plastics, PSU injection-molded parts are prone to internal stresses, which can lead to cracking or premature failure. Four main types of stress are commonly observed:

To minimize these stresses, it is essential to control mold temperature, part thickness, and cooling uniformity. For PSU, mold temperatures of around 130°C are generally recommended.

PSU requires specific processing conditions to achieve optimal results. Some key points include:

By following these processing requirements, manufacturers can ensure consistent part quality and prevent material breakdown.

PSU’s high viscosity and relatively low flow length-to-thickness ratio (around 80) require special attention in mold design. Some guidelines include:

With these measures, parts can achieve smooth surfaces, dimensional stability, and excellent performance.

The success of PSU injection molding depends on careful parameter control:

Balancing these settings ensures consistent molding quality and avoids common defects like brittleness, voids, or stress cracking.

PSU is a high-performance engineering plastic well-suited for injection molding functional components that require high heat resistance, mechanical strength, and dimensional stability. Although its high viscosity and tendency to generate internal stress present processing challenges, proper drying, optimized mold design, and careful process control can ensure reliable results.

For manufacturers seeking a durable material for demanding injection-molded parts, PSU offers significant advantages over conventional plastics.

If you are looking for high-quality PSU materials for injection molding, Shengwen is a reliable polysulfone supplier providing consistent quality and technical support for your applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.