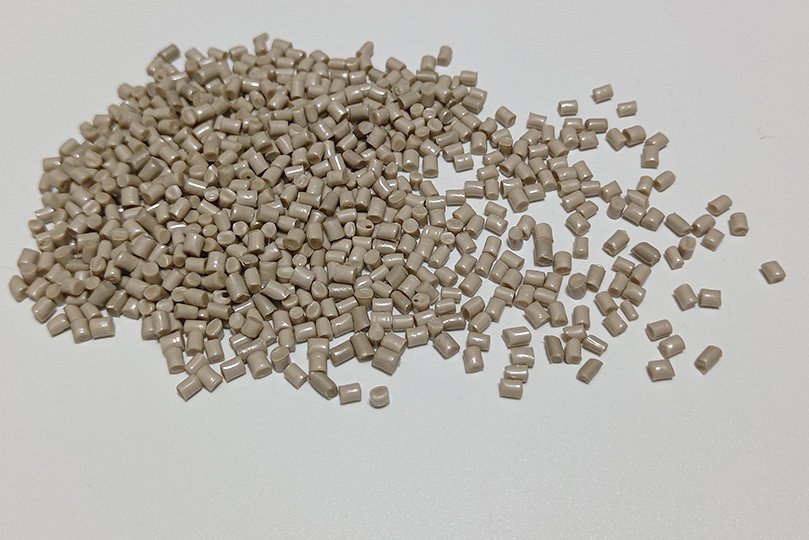

Have you ever heard of polyether ether ketone, or PEEK for short? If not, you're in for a treat. This high-performance thermoplastic has been making waves in various industries, including automotive and medical, due to its impressive combination of properties.

But what exactly is PEEK, and what makes it so special? PEEK is a semi-crystalline thermoplastic that is known for its strength, high-temperature resistance, and biocompatibility.

In this article, we'll dive deeper into why PEEk is becoming increasingly popular and, the potential for further use in the automotive industry.

PEEK is a member of the polyaryletherketone (PAEK) family, which includes other high-performance materials such as PEKK and PEEKK. In this section we will look at a few of the reasons why PEEK is becoming increasingly popular:

PEEK's high-temperature resistance, strength, lightweight, and chemical resistance make it an ideal choice for use in high-performance automotive applications.

Its use in automotive applications helps to improve the overall reliability and performance of vehicles.

PEEK is a cost-effective alternative to traditional materials such as metals and composites. Its ability to be molded into complex shapes and its resistance to abrasion and wear also helps to reduce the costs associated with maintenance and replacement.

PEEK is a sustainable material, with a low environmental impact and the ability to be recycled. Its use in automotive applications helps to reduce the overall environmental impact of vehicles.

PEEK is a versatile material that can be modified to meet the specific requirements of different applications. Its ability to be molded into complex shapes and its resistance to abrasion and wear make it an ideal choice for use in innovative automotive applications.

PEEK has the potential to be used in a wide range of applications in the automotive industry. Let's take a look at a few examples of the potential for further use of PEEK:

With its high-temperature resistance and strength, PEEK has the potential to be used in exterior automotive components such as grilles, spoilers, and mirror covers. This would provide a lightweight and durable alternative to traditional materials such as metals and composites.

PEEK's electrical insulating properties, combined with its high-temperature resistance, make it an ideal material for use in electrical components such as connectors, fuses, and wiring harnesses. This would improve the overall reliability and performance of these components.

PEEK has the potential to be used in a wide range of engine components, including valves, camshafts, and turbocharger components. Its high-temperature resistance, strength, and low coefficient of thermal expansion make it an ideal choice for these demanding applications.

PEEK's high strength and low weight make it an ideal material for use in suspension components such as shock absorbers, springs, and bushings. This would improve the overall performance and ride comfort of vehicles.

Are you looking for a high-performance material for your automotive applications? Look no further than PEEK from Tuntunplastic. Our PEEK products are manufactured to the highest standards, ensuring that you receive a reliable and consistent product every time.

Our team of experts is always available to help you choose the best PEEK product for your specific needs and answer any questions you may have. So why wait? Click here to place an order.

By continuing to use the site you agree to our privacy policy Terms and Conditions.