News

Site Editor

Site

/uploads/image/624e518adecd0.png

Here are some common materials used in the production of special engineering plastics along with their characteristics and applications.

Site

/uploads/image/624e518adecd0.png

Here are some common materials used in the production of special engineering plastics along with their characteristics and applications.

What Are the Materials Used to Make Special Engineering Plastic?

Views: 4875

Author: Site Editor

Publish Time: 2024-03-20

Origin: Site

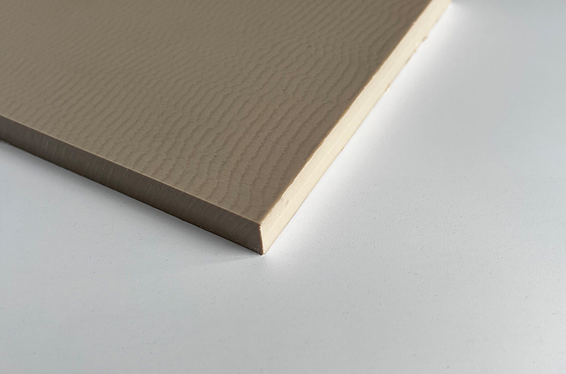

Special engineering plastics, also known as high-performance or specialty plastics, are a class of materials with exceptional mechanical, thermal, chemical, and electrical properties. These materials are tailored to meet specific requirements in demanding applications across various industries. Here are some common materials used in the production of special engineering plastics along with their characteristics and applications.

Polyetheretherketone (PEEK):

-

Characteristics: PEEK is known for its outstanding mechanical strength, chemical resistance, and high-temperature stability.

-

Applications: It is widely used in aerospace, automotive, medical, and electronics industries for components requiring high performance under harsh conditions, such as gears, bearings.

Polyethersulfone (PES):

-

Characteristics: PES exhibits excellent thermal stability, mechanical strength, chemical resistance, and dimensional stability.

-

Applications: PES is commonly used in medical, automotive, and aerospace industries for components such as medical devices, automotive parts, and aircraft interiors.

Polyether Block Amide (PEBA):

-

Characteristics: PEBA combines the flexibility of polyether segments with the strength and chemical resistance of polyamide segments.

-

Applications: PEBA is used in sports equipment, automotive, and industrial applications for products such as sports shoe soles, automotive hoses, and cable sheathing.

Polyphenylsulfone (PPSU):

-

Characteristics: PPSU exhibits high heat resistance, excellent chemical resistance, and good impact strength.

-

Applications: PPSU is used in medical, aerospace, and plumbing applications for components requiring sterilizability and durability, such as surgical instruments and aircraft interiors.

Polyimide (PI):

-

Characteristics: PI exhibits exceptional thermal stability, excellent electrical properties, and resistance to chemicals and radiation.

-

Applications: PI is extensively used in aerospace, electronics, and automotive industries for applications such as electrical insulation, printed circuit boards, and thermal barriers.

Polytetrafluoroethylene (PTFE):

-

Characteristics: PTFE is known for its low friction coefficient, excellent chemical resistance, and high-temperature stability.

-

Applications: It is commonly used in seals, gaskets, bearings, and coatings in industries such as automotive, chemical processing, and food processing.

Polyphenylene Sulfide (PPS):

-

Characteristics: PPS offers high mechanical strength, chemical resistance, and thermal stability.

-

Applications: PPS is used in automotive, electrical, and chemical industries for components such as pump parts, electrical connectors, and filter housings.

Liquid Crystal Polymer (LCP):

-

Characteristics: LCP has excellent mechanical properties, high-temperature resistance, and low thermal expansion.

-

Applications: LCP is used in electronic components, connectors, and miniaturized devices due to its dimensional stability and reliability.

Polyetherimide (PEI):

-

Characteristics: PEI offers high strength, stiffness, and heat resistance along with excellent flame retardancy.

-

Applications: PEI finds applications in automotive, aerospace, and electrical industries for components such as connectors, lighting fixtures, and aircraft interiors.

Polyvinylidene Fluoride (PVDF):

-

Characteristics: PVDF offers good chemical resistance, UV resistance, and high dielectric strength.

-

Applications: PVDF is used in chemical processing, electrical insulation, and renewable energy applications for components such as pipes, wire coatings, and solar panels.

Polyamide-imide (PAI):

-

Characteristics: PAI exhibits high thermal stability, mechanical strength, and resistance to wear and chemicals.

-

Applications: PAI is used in aerospace, automotive, and semiconductor industries for components such as bearings, gears, and semiconductor manufacturing equipment.

Fluorinated Ethylene Propylene (FEP):

-

Characteristics: FEP offers excellent chemical resistance, low friction, and high transparency.

-

Applications: FEP is used in chemical processing, semiconductor, and electrical industries for applications such as tubing, wire insulation, and lining materials.

These materials represent a diverse range of special engineering plastics tailored to meet the stringent requirements of modern industrial applications. Their unique properties contribute to advancements in technology, efficiency, and sustainability across various sectors.

If you need PPSU, PES, PSU, PEI,PEEK,PPS, PVDF, PTFE materials, please contact Shengwen. We will provide you with the best discount and the best service