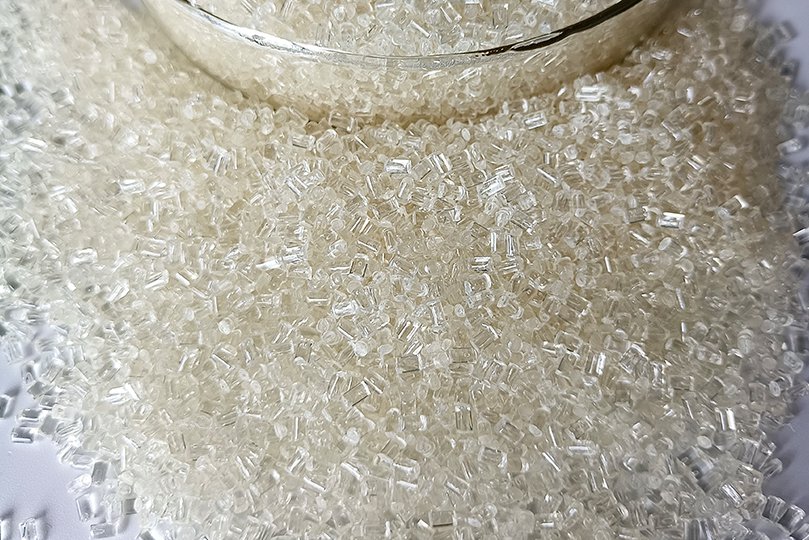

PSU

Overview :

PPSU (polyphenylene sulfone resin) is an amorphous polymer with superior rigidity and toughness, offering better impact resistance and chemical resistance than polyetherimide (PEI). PPSU is one kinds of amber transparent material, easy to color and processing, and its Heat Deflection Temperature can reach 196 ℃. Withstands over 1000 cycles of steam sterilization@134℃ without any significant loss of properties. Polyphenylsulfone (PPSU) has no melting point, reflecting its amorphous nature, and offers tensile strength up to 70 MPa (10152 psi).

According to the different application environment, the molding method can be injection, extrusion and blowing. As the highest performance material of sulfone polymers, PPSU has been approved by IS010993, NSF, ACS, WARS, UL94, Reach and RoSH. So PPSU has been widely used in medical sterilization boxes, handles of dental instruments, aircraft interiors and food trays, PEX water pipe joints, ventilator humidification tanks, baby bottles and other fields. Shop for PPSU Rods & Sheet >>

PPSU Material Properties and Data Sheet

| Typical Value | Testing Method | Unit | F1150 | F1250 | F1350 | M1150 | ||

| MFR @ 365℃/5kg | ISO 1133 | g/10min | 10-18 | 18-28 | 28-38 | 15-20 | ||

| PPSU Density | ISO 1183 | g/cmᶟ | 1.29 | 1.29 | 1.29 | 1.28 | ||

| Moisture Absorption, Equilibrium 23℃/50% r.h | ISO 62 | % | 0.6 | 0.6 | 0.6 | 0.3 | ||

| Mold shrinkage-Flow | ISO 2577, 294-4 | % | 0.9 | 0.9 | 0.9 | 0.9 | ||

| HDT/A @1.8MPa | ISO 75-1/-2 | ℃ | 196 | 196 | 196 | 185 | ||

| Tensile Strength | ISO 527-1/-2 | MPa | 70 | 70 | 70 | 75 | ||

| Tensile Modulus | ISO 527-1/-2 | MPa | 2270 | 2270 | 2270 | 2690 | ||

| Tensile Elongation(Yield) | ISO 527-1/-2 | % | 7.8 | 7.8 | 7.8 | 7.0 | ||

| Flexural Strength | ISO 178 | MPa | 105 | 105 | 105 | 105 | ||

| Flexural Modulus | ISO 178 | MPa | 2400 | 2400 | 2400 | 2760 | ||

| Notched Izod Impact | ISO 180/A | KJ/㎡ | 68 | 68 | 68 | 10.0 | ||

Note: As can be seen from the data sheet above, Polyphenylsulfone (PPSU) is an amorphous, heat-resistant and transparent high-performance thermoplastic. The polymer is known for its high toughness, high flexural and tensile strength, excellent hydrolytic stability and good resistance to chemicals and heat. Compared to PSU and PES, it delivers the highest performance of our sulfone polymers, offering superior mechanical properties and chemical resistance.

Typical Application

PPSU is often an excellent choice for components that are exposed to high temperatures and corrosive media due to its exceptional chemical resistance. PPSU is widely used for aircraft interior parts, instrument handles, medical instrument components and so on.

Dental and Surgical Instruments: PPSU is a good substitute for metal in the applications of medical devices and accessories, because it is light and strong.

Food Service: PPSU is biologically inert and BPA-free, which can withstand prolonged and repeated exposure to hot water, steam, oil or grease, making it to be an excellent candidate for food service applications. Learn Why PPSU is the Ideal Material for Food-Contact Applications.

Aircraft Interiors: PPSU series products are used in aircraft cabin interiors, which requiring low heat release, low smoke generation and low toxic gas emissions. They offer exceptional toughness and impact strength, superior resistance to cleaning agents and chemical disinfectants, and molded-in color to eliminate painting.

Dental and Surgical Instruments

Food Service Trays and Baby Bottles

Aircraft Interiors

FAQ:

What is PPSU Plastic?

PPSU (Polyphenylsulfone) is a type of thermoplastic polymer known for its high temperature resistance, chemical resistance, and strength. PPSU plastic is often used in applications where stability under harsh conditions is important, such as medical devices and automotive components.

Q1

What are the characteristics of PPSU plastic?

PPSU plastic properties include:High temperature resistance, Chemical resistance, Dimensional stability, Radiation resistance, High impact resistance, Good electrical insulation and Low moisture absorption.

Q2

Whether to provide the sample and the delivery time of the sample ?

We can provide a sample of 3kg in stock within 5 working days.

Q3

Can you provide customized services?

Yes, all our raw materials can be customized, such as adding glass fiber, carbon fiber and other fillers, or making PPSU boards, PPSU sheet and PPSU rods of different sizes. Click for details to learn more>>

Q4

Can you provide the quality certificate of the products?

Of course. All of our products are proven to be perfectly compliant with FDA, REACH and RoHS safety regulatory, and so on. If you need, you can contact us to check the relevant documents.

Q5

Are you manufacturer or trading company?

We are integral part of industry and trade. Both the agency of some products, but also a factory for product development and production.

Q6

About bulk order leading time?

It will take about 15~30 working days from order confirmation to production completion. Specific communication can be coordinated to the time acceptable to both side.

Q7