Polysulfone

Overview :

PA12 (polyamide 12) is a microcrystalline transparent polyamide with the transparency up to 90%, easy to color and process. This material has the advantages of low density-1.02g/cm³, high toughness, high rigidity and excellent chemical resistance. Compared with copolyester (PCTG), PA12 has higher temperature resistance (HDT 125℃) and lower density which can increase the yield of production and reduce production costs. The material PA12 approved by REACH, ROHS and other environmental protection certifications. Because of BPA-free, PA12 can be used in the production and processing of food containers. As a special polyamide product, it can be used in optical glasses frames, lenses, earphone accessories, smart wearable shells, electronic connectors, small household appliances, automotive fuel storage cups and other fields.

The Main Specifications and Properties of PA12 Transparent Nylon

| Typical Value | Testing Method | Unit | SAM639 | TN-90 | SAM680eCo | |

| Hardness | ISO 868 | D | 83 | 83 | 82 | |

| Density | ISO 1183 | g/cmᶟ | 1.03 | 1.02 | 1.02 | |

| Tensile modulus (23 ℃) | ISO 527-2 | MPa | 1600 | 1500 | 1600 | |

| Tensile stress (yield, 23 ℃) | ISO 527-2/50 | MPa | 70 | 65 | 65 | |

| Bending modulus | ISO 178 | MPa | 1700 | 1600 | 1750 | |

| Ball pressure hardness | ISO 2039-1 | MPa | 125 | 120 | 120 | |

| Thermal deformation temperature | ISO 75-2/B | ℃ | 125 | 135 | 125 | |

| Surface resistivity | IEC 60093 | / | 1.0E + 14ohms | 1.0E + 14ohms | 1.0E + 14ohms | |

| Glass transition temperature (10K/min) | ISO 11357-2 | ℃ | 130 | 140 | 128 | |

| UL flame-retardant rating | UL 94 | / | HB | HB | HB | |

Typical Application

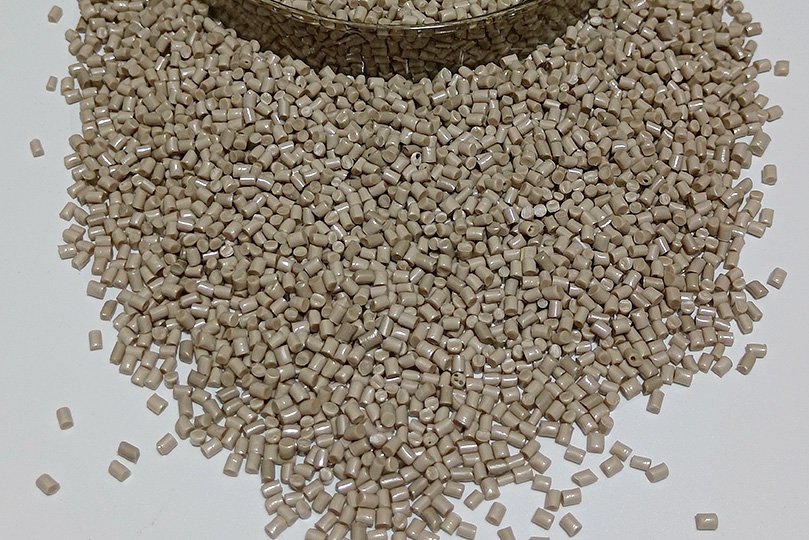

Polyamide 12 is manufactured through a process called polycondensation, which involves the reaction of diamines and dicarboxylic acids. This process results in the formation of nylon polymer chains, creating the raw material known as PA12. Once PA12 is produced, it can be processed into various forms such as pellets, sheets, and filaments for 3D printing.

Polyamide 12 is a versatile engineering plastic that finds applications across a range of industries due to its unique combination of properties. Here are some common industries and applications where Polyamide 12 is commonly used:

Electronic Appliances

Optical Glasses Frames And Lenses

Water Meters

These are just a few examples of the wide-ranging applications of Polyamide 12 in different industries. Its versatility, durability, and excellent combination of mechanical and chemical properties make it a preferred choice for numerous engineering challenges across various sectors.

FAQ:

What is PA12 Material?

PA 12 (also known as Nylon 12) is a good general-use plastic with broad additive applications and is known for its toughness, tensile strength, impact strength and ability to flex without fracture.

Q1

What are the advantages of PA12?

Polyamide 12 has many advantages such as low water absorbing nylon,good chemical resistance and ability to accept high loading of fillers.

Q2

What's the difference between PA12 and ABS?

Polyamide 12 is more durable and chemical-resistant than ABS and resins. ABS melts at 105 °C, whereas PA 12 melts at 187 °C. Since the polyamide is also stress and vibration-resistant, it is often used in both the aerospace and automotive industries.

Q3

Is Nylon PA12 waterproof?

In terms of water absorption, Nylon PA 12 absorbs very little moisture, is water-resistant but not waterproof.

Q4

What's the differences between nylon 12 and nylon 6?

Nylon 12 and Nylon 6 have distinct properties that make them suitable for different applications. Nylon 12 is known for its chemical resistance, flexibility, and impact resistance, while Nylon 6 offers higher mechanical strength and stiffness. The choice between the two depends on the specific requirements of the application and the desired material properties.

Q5

Whether to provide the sample and the delivery time of the sample ?

We can provide a sample of 3kg in stock within 5 working days.

Q6

Can you provide customized services?

Yes, all our raw materials can be customized, such as adding glass fiber, carbon fiber and other fillers, or making boards and rods of different sizes. Click for details to learn more>>

Q7

Can you provide the quality certificate of the products?

Of course. All of our products are proven to be perfectly compliant with FDA, REACH and RoHS safety regulatory, and so on. If you need, you can contact us to check the relevant documents.

Q8

Are you manufacturer or trading company?

We are integral part of industry and trade. Both the agency of some products, but also a factory for product development and production.

Q9

About bulk order leading time?

It will take about 15~30 working days from order confirmation to production completion. Specific communication can be coordinated to the time acceptable to both side.

Q10